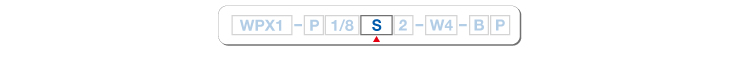

WPX1/WPX1C DC Brush Motor & Gear

Geared motor Specification

Scroll Table

| Geared motor model | S | M | L | DS | DM |

|---|---|---|---|---|---|

| Rated voltage | DC24V | DC12V | |||

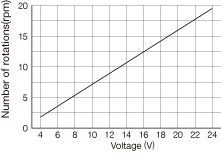

| RPM (load:100mNm) |

19.5rpm (24V input) |

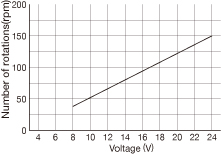

150rpm (24V input) |

225rpm (24V input) |

18rpm (12V input) |

140rpm (12V input) |

| Operation voltage | 4V to 24V | 8V to 24V | 3V to 12V | 6V to 12V | |

| Current | Less than 200mA |

Less than 300mA |

Less than 450mA |

Less than 300mA |

Less than 600mA |

Caution : The consumption current described above is the value during normal operations.

An approximately threefold inrush current occurs during rotation startup.

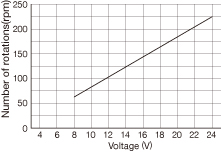

24VDC Brush Motor & Gear

S

Recommended motor

voltage 4V to 24V

Consumption current 200mA max

M

Recommended motor

voltage 8V to 24V

Consumption current 300mA max

L

Recommended motor

voltage 8V to 24V

Consumption current 450mA max

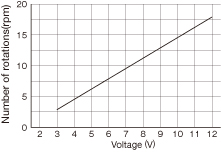

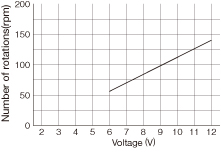

12VDC Brush Motor & Gear

DS

Recommended motor

voltage 3V to 12V

Consumption current 300mA max

DM

Recommended motor

voltage 6V to 12V

Consumption current 600mA max

Caution :

*1. The specified current consumption reflects normal operating conditions. Upon startup, an inrush current approximately three times greater than the normal value may be generated.

*2. The minimum operating voltage may vary depending on tube size, material, operating environment, and other factors. Please verify performance under actual operating conditions.

*3. A short circuit between terminals may occur due to motor end-of-life or between commutator slits under certain operating environments and conditions.To prevent circuit burnout or damage to the system, please implement appropriate protective measures, such as using fuses or other circuit protection devices.

Flow amount benchmark (flow amount per rotation)

Scroll Table

| Size code | 1.6mm (1/16”) |

2.4mm (3/32”) |

3.2mm (1/8”) |

4.8mm (3/16”) |

||||

|---|---|---|---|---|---|---|---|---|

| Number of rollers | 2 | 4 | 2 | 4 | 2 | 4 | 2 | 4 |

| Flow amount per rotation (ml) | 0.17 | 0.15 | 0.35 | 0.3 | 0.6 | 0.5 | 1.2 | 0.9 |

Note.

1. The flow amount rotation is based on laboratory test at WELCO. This may vary depending on operating environment, lot tolerances, and other factors. Please veryfiy performance under actual operation conditions.

2. The reference flow rate of the pump is determined by the product of flow amount per rotationand motor speed.

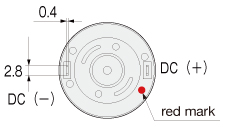

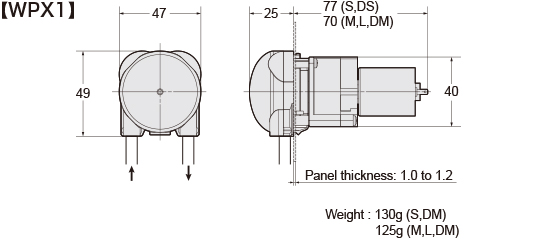

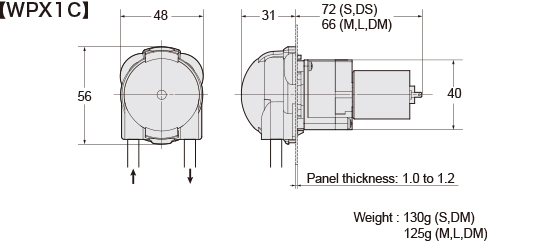

Dimensions (unit: mm)

Motor wiring diagrams