WPX1/WPX1C Stepper motor

Geared motor Specification

Scroll Table

| Geared motor code | FB | FA |

|---|---|---|

| Configuration | Hybrid stepper motor & 1:64 Gear ratio | Hybrid stepper motor & 1:8 Gear ratio |

| Number of phases and motor type | 2 phase/BI polar system | |

| Rated voltage | 1.92V | |

| Rated current | 0.8A/Phase | |

| Step angle | 0.0141°(Half step) | 0.1125°(Half step) |

| RPM | 0 to 20rpm | 20 to 150rpm |

| Duty ratio | Max. 50% | |

| Winding resistance | 2.4Ω±10% | |

| Inductance | 2.5mH | |

| Motor insulation class | B | |

| Motor rated temperature | less than 80°C (176°F) | |

| Motor life *1 | 5,000hrs | |

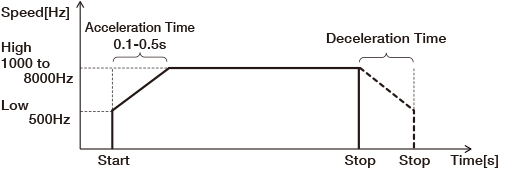

<1-2P Drive Method>

Scroll Table

| F-Low(Initial speed) | 500Hz(pps) |

|---|---|

| F-Hight(Operetion speed) | over 1000Hz(pps) use Max: 8000Hz(pps) |

| Acceleration/Deceleration time |

The given value from 0.1 to 0.5s or 1.0s |

| Operetion current |

Any value below the Maximum rating. |

| Rating rotation |

FB motor with 1:64gear 【0~20rpm ⇒ 0~8533Hz(1-2P)】 |

The characteristic of our Peristerltic Pump products is an initial hight torque value. It's about 2 or 3 times higher compared to the torque required to maintain a constant velocity once the tube has conformed to the shape of the roller.

When you have a step-motor driven by a high freqency, it is necessary to apply the frequency described in above.

In deceleration, the frequency can be reduced gradually as well as in acceletion or within being cut off suddenly.

One point advice

If Pump load is high and rotor does not work, please try to apply 10-20% higher current than rated current of motor during

the acceleration of trapezoidal drive above. Once Pump reaches at the constant speed, please set it back to the rated current.

Flow amount benchmark (flow amount per rotation)

Scroll Table

| Inside diameter of tube (inches) | 1.6mm (1/16”) |

2.4mm (3/32”) |

3.2mm (1/8”) |

4.8mm (3/16”) |

||||

|---|---|---|---|---|---|---|---|---|

| Number of rollers | 2 | 4 | 2 | 4 | 2 | 4 | 2 | 4 |

| Flow amount per rotation (ml) | 0.17 | 0.15 | 0.35 | 0.3 | 0.6 | 0.5 | 1.2 | 0.9 |

Caution: Tube type EL1/8", F3/16" cannot be used with four rollers due to its high hardness.

1. The flow amount rotation is based on laboratory test at WELCO. This may vary depending on operating environment, lot tolerances, and other factors. Please veryfiy performance under actual operation conditions.

2. The reference flow rate of the pump is determined by the product of flow amount per rotation and motor speed.

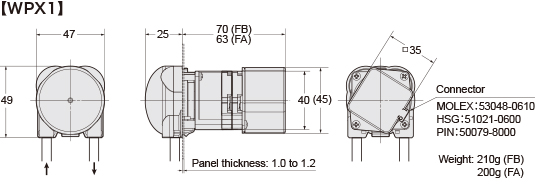

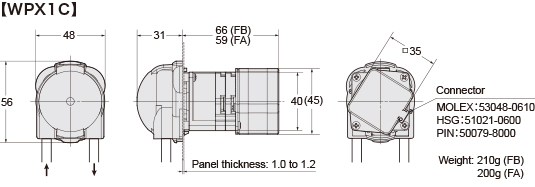

Dimensions (unit: mm)

Motor wiring diagram