WPM Pump series

WPM1

The rollers are made of POM, but other parts are made of super engineering plastic (PSU) which offers excellent corrosion resistance. This allows the pump to handle acids, strong alkalis, and any other general chemical solutions.

Scroll Table

| Liquid temperature | 5°C to 50°C (41℉ to 122℉) |

|---|---|

| Material (Pump cassette) | PSU (Casstte, Rotor, others) , POM (Roller,others) |

| Autoclave | Not applicable |

WPM2

All parts of the WPM2 cassette are made of a super engineering plastic (PSU), which provides superior chemical resistance and enables high-temperature liquid transfer compared to the WPM1 pump series. The entire cassette is also autoclavable.

Scroll Table

| Liquid temperature | 5°C to 80°C (41℉ to 176℉) |

|---|---|

| Material (Pump cassette) | PSU (All parts) |

| Autoclave | Condition: 0.1MPa, 121°C, 20min (only pump cassette) |

Autoclave sterilization is assumed to be performed up to 30 times. Please note that not all tube types are suitable for autoclaving. For specific tubing compatibility, please contact our sales representative. Autoclaving the cassette with the tubing installed may result in a decrease in flow rate.

Please evaluate under actual operating conditions, and if necessary, remove the tubing before autoclaving.

General specification

Scroll Table

| Pump series | WPM1 | WPM2 |

|---|---|---|

| Recommended installation height | 2 meter (6.8 ft.) max | |

| Liquid temperature | 5°C to 80°C (41 to 122°F) | 5°C to 80°C (41 to 176°F) |

| Operating temperature | 0 to 50°C (32 to 122°F) (No freezing) | |

| Operating humidity | 20 to 80% RH (No condensation) | |

| Max. Discharge pressure *1 | 90kPa (Pharmed BPT) Silicone 80kPa or less | |

| Autoclave | Not applicable | Condition: 0.1MPa, 121°C, 20min Only the Pump parts. *2 |

| Material (Pump cassette) | PSU(Casstte, Rotor, others) POM (Roller, others) |

PSU (All) |

| Certifications & Approvals | *UL: Except CA type |

|

Note:

* 1

If the discharge side becomes blocked, the tubing may rupture, potentially resulting in a hazardous situation.

To prevent this, ensure that the discharge side is designed so that the pressure remains below the pump's discharge pressure.

*2

Autoclave sterilization is assumed to be performed up to 30 times. Please note that not all tube types are suitable for autoclaving. For specific tubing compatibility, please contact our sales representative.

Autoclaving the cassette with the tubing installed may result in a decrease in flow rate.

Please evaluate under actual operating conditions, and if necessary, remove the tubing before autoclaving.

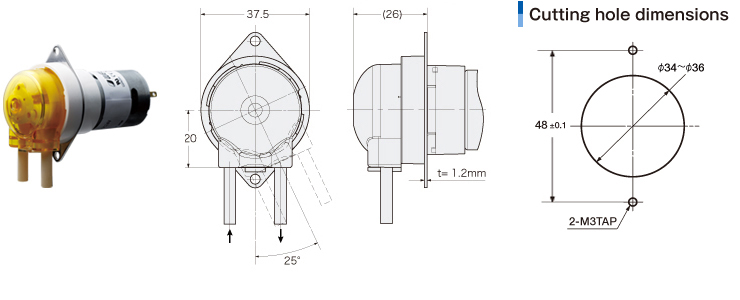

using screws (unit: mm)

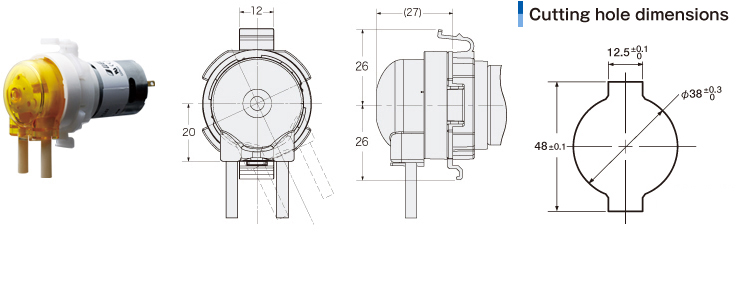

one-touch mounting (unit: mm)