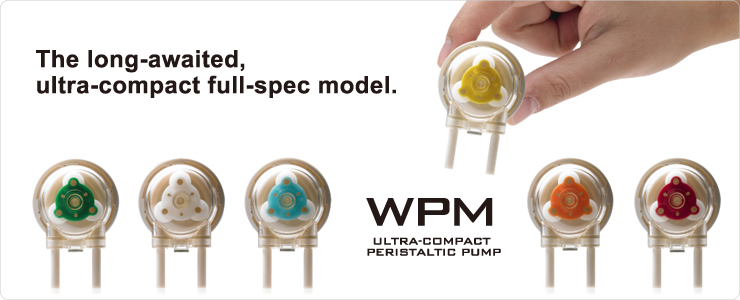

WPM Products configuration

38 mm diameter ultra-compact full-spec model

WPM1 Feature

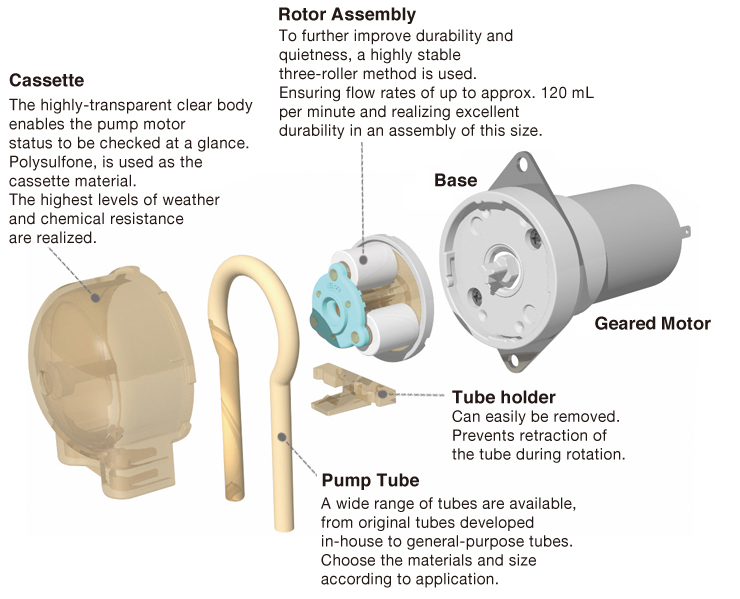

The rollers are made of POM, but other parts are made of super engineering plastic (PSU) which offers excellent corrosion resistance. This allows the pump to handle acids, strong alkalis, and any other general chemical solutions.

Scroll Table

| Liquid temperature | 5°C to 50°C (41℉ to 122℉) |

|---|---|

| Material (Pump cassette) | PSU (Casstte, Rotor, others) , POM (Roller,others) |

| Autoclave | Not applicable |

WPM2 Feature

All parts of the WPM2 cassette are made of a super engineering plastic (PSU), which provides superior chemical resistance and enables high-temperature liquid transfer compared to the WPM1 pump series. The entire cassette is also autoclavable.

Scroll Table

| Liquid temperature | 5°C to 80°C (41℉ to 176℉) |

|---|---|

| Material (Pump cassette) | PSU (All parts) |

| Autoclave | Condition: 0.1MPa, 121°C, 20min (only pump cassette) |

Note:

Autoclave sterilization is assumed to be performed up to 30 times. Please note that not all tube types are suitable for autoclaving. For specific tubing compatibility, please contact our sales representative. Autoclaving the cassette with the tubing installed may result in a decrease in flow rate.

Please evaluate under actual operating conditions, and if necessary, remove the tubing before autoclaving.

Motor variation

The lineup also includes various types of motors for mounting, such as 12 and 24VDC low-speed and high-speed motors, stepper motors, brushless motors, etc.

Pump tube type

Scroll Table

| Tube type | Product description | Regulately compliance/meets |

|---|---|---|

| P PHARMED BPT |

* Thermoplastic elastomer (TPE) tube for bioprocess application * Meets USP class VI criteria for use in medical devices and pharmaceuticals * Good resistant to general chemicals as TPE tube |

USP Class VI |

| NF Tygon Food A-60-F (Tygon A-60-F) |

* Thermoplastic elastomer (TPE) tube for food, dairy and sanitary industries * Good resistant to general chemicals as TPE tube |

NSF 51 3-A |

| S Tygon 3355 |

* High-performace and platinum-cured silicone tube * 3 to 5 times longer life compared to typical platinum-cured silicone tubes |

FDA 21 CFR Part 177.2600 USP Class VI |

| F Versilon F-5500-A (FLURAN F-5500-A) |

* Fluorelastomer tube for strong corrosive chemical and oil transfers * Ozone and UV light resistant |

- |

| W W TUBE |

* WELCO's original tube designed for peristaltic pump * Great resistant to corrosive chemicals * Inner layer: Polyolefin elastomer, Outer layer: Thermoplastic elastomer |

- |

| TA Transmaster TM-15 |

* Thermoplastic Olefin tube for chemicals and ink transfer * Great resistant to corrosive chemicals |

Tygon, Versilon, Pharmed and Fluran are manufactured by Saint-Gobain Group.

Please refer to chemical resistant properties for tube selection. It is the user’s responsibility to ensure the suitability and safety of tube for all intended uses, including establishing the compatibility of any fluid with the tubing through which it is transmitted. Laboratory, field or clinical tests must be conducted in accordance with applicable requirements in order to determine the safety and effectiveness for use of tubing in any particular application. If intended for medical use, it is the user’s responsibility to ensure that the tubing to be used complies with all applicable medical regulatory requirements.

General specifications

Scroll Table

| Pump series | WPM1 | WPM2 |

|---|---|---|

| Recommended installation height | 2 meter (6.8 ft.) max | |

| Liquid temperature | 5°C to 80°C (41 to 122°F) | 5°C to 80°C (41 to 176°F) |

| Operating temperature | 0 to 50°C (32 to 122°F) (No freezing) | |

| Operating humidity | 20 to 80% RH (No condensation) | |

| Max. Discharge pressure *1 | 90kPa (Pharmed BPT) Silicone 80kPa or less | |

| Autoclave | Not applicable | Condition: 0.1MPa, 121°C, 20min Only the Pump parts. *2 |

| Material (Pump cassette) | PSU(Casstte, Rotor, others) POM (Roller, others) | PSU (All) |

| Certifications & Approvals | *UL: Except CA type |

|

Note:

*1

If the discharge side becomes blocked, the tubing may rupture, potentially resulting in a hazardous situation.

To prevent this, ensure that the discharge side is designed so that the pressure remains below the pump's discharge pressure.

*2

Autoclave sterilization is assumed to be performed up to 30 times. Please note that not all tube types are suitable for autoclaving. For specific tubing compatibility, please contact our sales representative.

Autoclaving the cassette with the tubing installed may result in a decrease in flow rate.

Please evaluate under actual operating conditions, and if necessary, remove the tubing before autoclaving.