WP1000/1100 Products configuration

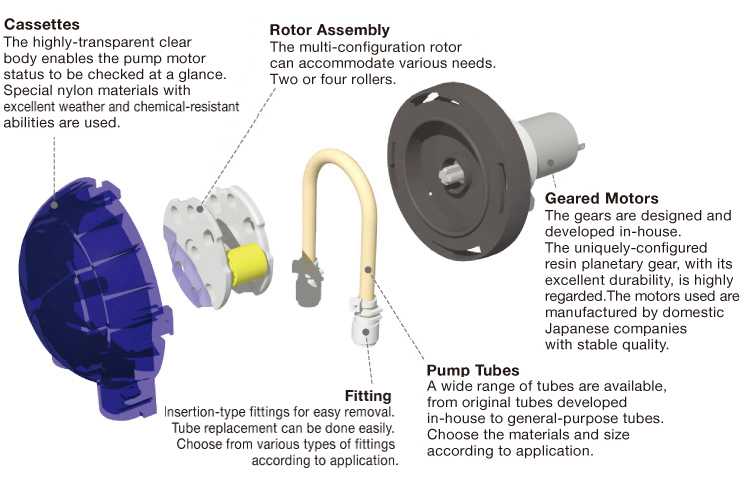

A simple configuration is achieved by incorporating multiple functions into each part.

Simple configuration

WELCO peristaltic pumps use parts manufactured entirely using high-quality Japanese technology. The pumps meet a wide range of needs from 0.5 mL to a maximum of 700mL per minute by using various combinations of parts.

Various motors can be mounted according to need

Motor variation

The lineup also includes various types of motors for mounting, such as 12 and 24VDC low-speed and high-speed motors, AC motors, stepper motors, brushless motors, etc.

Pump tube type: Materials

A varlety of materials can be selected by fluid type.

Scroll Table

| Tube type | Product Description | Regulately compliance/meets |

|---|---|---|

| P PHARMED BPT |

* Thermoplastic elastomer (TPE) tube for bioprocess application * Meets USP class VI criteria for use in medical devices and pharmaceuticals * Good resistant to general chemicals as TPE tube |

USP Class VI |

| N Tygon Chem A-60-G (Tygon A-60-G) |

* Thermoplastic elastomer (TPE) tube for industrial use * Good resistant to general chemicals as TPE tube |

- |

| NF Tygon Food A-60-F (Tygon A-60-F) |

* Thermoplastic elastomer (TPE) tube for food, dairy and sanitary industries * Good resistant to general chemicals as TPE tube |

NSF 51 3-A |

| S Tygon 3355/3350 |

* High-performance and platinum-cured silicone tube * Ultra-smooth inner bore reduces potential for particle entrapment * Excellent fluid flow characteristics. |

FDA 21 CFR Part 177.2600 USP Class VI 3-A (3350 only) |

| F Versilon F-5500-A (FLURAN F-5500-A) |

* Fluorelastomer tube for strong corrosive chemical and oil transfers * Ozone and UV light resistant |

- |

| U Versilon 2001 (TYGON 2001) |

* Plasticizer and oil free polyolefin elastomer tube * Great resistant to corrosive chemicals |

FDA 21 CFR Part 177.2600 |

| EL Tygon Lab E-LFL (Tygon S3 E-LFL) |

* Suitable for food and bioprocess application * Higher resistance to gas permeation compared to silicone tube * Good resistant to general chemicals |

FDA 21 CFR Part 177.2600 USP Class VI NSF-51 EU 10/2011 |

| XL Tygon Food XL-60 (Tygon XL-60) |

* Suitable for food and beverage application * Good resistant to general chemicals |

FDA 21 CFR Part 177.2600 NSF 51 EU 10/2011 |

| W W Tube |

* WELCO's original tube designed for peristaltic pump * Great resistant to corrosive chemicals * Inner layer: Polyolefin elastomer, Outer layer: Thermoplastic elastomer |

- |

Note: Tygon, Pharmed, Norprene, Fluran and Tygoprene, Versilon are manufactured by Saint-Gobain Group.

Please refer to chemical resistant properties for tube selection. It is the user’s responsibility to ensure the suitability and safety of tube for all intended uses, including establishing the compatibility of any fluid with the tubing through which it is transmitted. Laboratory, field or clinical tests must be conducted in accordance with applicable requirements in order to determine the safety and effectiveness for use of tubing in any particular application. If intended for medical use, it is the user’s responsibility to ensure that the tubing to be used complies with all applicable medical regulatory requirements.

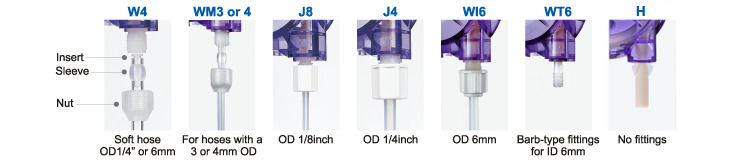

Types of tube fitting

A variety of fittings can be selected according to applications.

General specification

Scroll Table

| Recommended installation height | 2 meter (6.8 ft.) max |

|---|---|

| Liquid temperature | 5 to 50°C (41°F to 122°F) |

| Operating temperature | 0 to 50°C (32°F to 122°F) |

| Operating humidity | 20 to 80% RH (No condensation) |

| Certifications & Approvals |

|